Most Popular Products

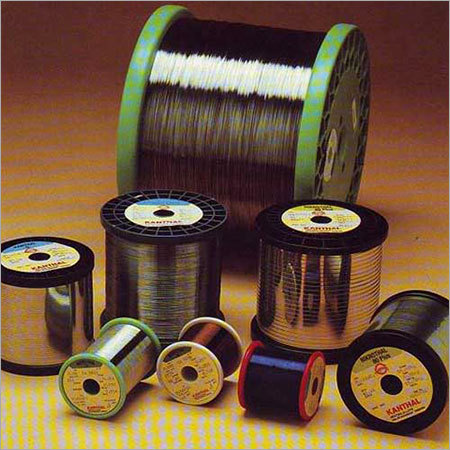

Precision Wire

Precision Wire Specification

- Cable Length

- Custom cut

- Temperature

- -60C to +260C

- Conductor Type

- Solid / Stranded

- No Of Core

- Single core

- Product Type

- Precision Wire

- Material

- Stainless Steel

- Function

- Electrical conduction

- Usage

- Industrial, Electronic Applications

- Voltage Surge

- Low to moderate

- Frequency (MHz)

- Applicable for signals up to 1000 MHz

- Rated Voltage

- 600 V

- Rated Current

- Varies as per size

- Cable Capacity

- Varies depending on diameter and material

- Insulation Material

- PTFE/None

- Conductor Material

- Stainless Steel

- Length

- Customizable / As per requirement

- Size

- 0.02 mm to 2.0 mm dia

- Color

- Silver

- Diameter

- 0.02 mm to 2.0 mm

- Application

- Medical instruments, Electronics, Precision devices

- Surface Finish

- Bright or matte

- Tensile Strength

- High tensile

- Flexibility

- High

- Magnetism

- Non-magnetic or low magnetic, depending on grade

- Tolerance

- ±0.001 mm

- Packaging Type

- Coil / Spool / Reel

- Standard

- ASTM/AISI

- Corrosion Resistance

- Excellent

Precision Wire Trade Information

- Payment Terms

- Cash on Delivery (COD), Telegraphic Transfer (T/T), Cheque

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Precision Wire

The Precision Wires, offered by us, are widely used in electronic components like resistors and potentiometers, in computer disk drives, for low temperature heating, in guitar strings, and applicable in electronics, audio & chemical industries and medical field as well. Furthermore, fabricated using optimum quality raw materials by employing innovative tools and techniques, these Precision Wires are having high strength, fine finish, high longevity, good conductivity, and resistance against detrimental effects such as high temperature, abrasion, corrosion, breakage etc. Aside from all this, we offer these wires in large number of specifications at very nominal prices.

Available range: 0.015mm up to 0.12mm.

Available range: 0.015mm up to 0.12mm.

Surface Finish and Flexibility

Precision Wire is supplied in two finish options, bright or matte, to cater to different functional and aesthetic preferences. The high flexibility of the wire ensures suitability in intricate assemblies and precision devices, while its well-controlled surface finish delivers consistent conductivity and corrosion protection in demanding environments.

Superior Performance in Electronics and Industrial Applications

This stainless steel wire is distinguished by its excellent tensile strength and corrosion resistance. Designed for durability, it successfully conducts electricity in industrial and electronic circuits. Its capacity to handle signals up to 1000 MHz makes it apt for high-frequency medical instruments and advanced electronics.

Tailored Specifications for Diverse Requirements

Available as single core, in diameters from 0.02 mm to 2.0 mm, and packaged in coil, spool, or reel formats, this wire suits various needs. Custom lengths and options for solid or stranded conductors make it ideal for precise requirements, from laboratory equipment to production line use.

FAQs of Precision Wire:

Q: How is the surface finish chosen for Precision Wire, and what are its benefits?

A: The surface finish of Precision Wire can be selected as either bright or matte according to application needs. Bright finishes are preferred for visibility and aesthetics, while matte provides a subdued look and can reduce reflection. Both finishes offer excellent corrosion resistance and stable electrical conduction.Q: What is the process for ordering Precision Wire with custom specifications?

A: To order custom Precision Wire, specify the required diameter (0.02 mm to 2.0 mm), length, surface finish, conductor type (solid or stranded), insulation material, and packaging format. Distributors, exporters, suppliers, and traders in India can accommodate these details for tailored solutions.Q: Where is Precision Wire most commonly used, and who are the typical buyers?

A: Precision Wire is widely utilized in medical instruments, advanced electronics, and precision devices, where high flexibility, corrosion resistance, and strength are essential. Typical buyers include industrial manufacturers, research institutions, electronic assemblers, and hospitals.Q: What are the advantages of using stainless steel as the conductor material?

A: Stainless steel provides excellent tensile strength, corrosion resistance, and stability under temperature extremes (from -60C to +260C). It is non-magnetic or low magnetic, depending on the grade, which is beneficial for sensitive electronic applications and medical devices.Q: How does Precision Wire support electrical conduction in high-frequency applications?

A: Precision Wire is engineered to minimize voltage surge and maintain efficient signal transmission up to 1000 MHz. Its tight tolerance (0.001 mm) and choice of insulation (PTFE or none) help ensure reliable performance in industrial and electronic environments.Q: What packaging options are available for Precision Wire?

A: Precision Wire is offered in coils, spools, or reels to suit specific handling and installation needs. The packaging type is chosen based on order quantity, wire length, and user preference for ease of storage and deployment.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Heating Alloy Wire Category

Heating Alloy Wire Roll

Minimum Order Quantity : 01 Unit

Rated Voltage : 220250 V

Conductor Material : NickelChromium

Size : Available in different gauges (e.g., SWG 836)

Color : Silver/Grey Metallic

Diameter : 0.2 mm to 2.0 mm (varies by SWG)

|

PR SHAH & CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |