Apm Radiant Tube

Apm Radiant Tube Specification

- Product Type

- Radiant Tube

- Material

- Apm Alloy (Advanced Powder Metallurgy)

- Type

- Seamless

- Shape

- Round

- Technique

- Hot Rolled/Extruded

- Surface Treatment

- Polished

- Standard

- ASTM / DIN / EN

- Outer Diameter

- As per specification

- Length

- Custom Lengths Available

- Inside Diameter

- As per customer requirement

- Wall Thickness

- 3 mm - 10 mm

- Tensile Strength

- High (Up to 1200 MPa)

- Grade

- Apm Special Alloy

- Size

- Customized

- Color

- Metallic Grey

- Usage

- Gas fired and electric radiant tube furnace systems

- Connection Type

- Plain Ends / Flanged

- Heat Resistance

- Up to 1250°C operating temperature

- Corrosion Resistance

- Excellent against carburizing and nitriding environments

- Manufacturing Process

- Powder Metallurgy Advanced Process

- Feature

- Superior oxidation resistance

- Application

- Industrial Furnaces, Heat-Treatment Plants

- Density

- ~7.8 g/cm³

- Expansion Coefficient

- Low, suitable for high thermal cycling

Apm Radiant Tube Trade Information

- Payment Terms

- Cash on Delivery (COD), Telegraphic Transfer (T/T), Cheque

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Apm Radiant Tube

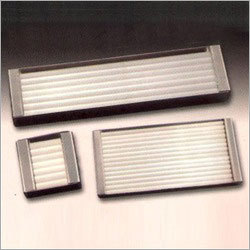

Constructed using optimum quality raw materials with the support of advanced tools and techniques, our APM & Radiant Tubes are having lots of quality attributes such as robust structure, high tensile strength, right dimension, optimum finish, smooth & strong installation, and very strong resistance to adverse conditions such as abrasion, corrosion, impacts, high pressure that ensure their very low maintenance, and high reliability. Besides, we offer these products at very reasonable prices in different specifications as per demands.

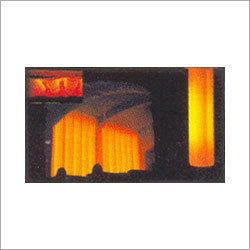

Furthermore, APM & Radiant Tubes are used for gas or electrically heated furnace. Complete assemblies with inner tubes (gas) or perfect and favorable electric heating elements. Standard dimensions from 26-260mm outer diameter 1.02"-10.2".

Advanced Alloy Technology for Enhanced Performance

Crafted from Apm special alloy via powder metallurgy, the radiant tube provides unmatched heat resistance, corrosion durability, and mechanical strength, supporting continuous operation in demanding furnace environments. Its seamless, hot rolled or extruded design guarantees high reliability and longevity under repeated thermal cycling.

Customizable Specifications for Versatile Applications

With options for inside and outer diameters, wall thickness, length, and connection type, the Apm Radiant Tube is customized to fit unique furnace designs and processes. Whether you require polished surfaces, flanged or plain ends, our solutions adhere to ASTM, DIN, and EN standards.

Optimized for Gas and Electric Furnace Systems

Highly suited for both electric and gas-fired radiant tube furnace systems, its low expansion coefficient minimizes thermal stress, ensuring consistent performance through fluctuating temperature cycles. Ideal for use in industrial heat-treatment plants and manufacturing facilities.

FAQs of Apm Radiant Tube:

Q: How does the Apm Radiant Tube withstand high operating temperatures?

A: The tube is manufactured from a special Apm alloy using advanced powder metallurgy, enabling it to maintain structural integrity and performance at temperatures up to 1250C, making it suitable for demanding industrial furnace applications.Q: What are the key advantages of using Apm Radiant Tubes in heat-treatment plants?

A: Apm Radiant Tubes offer excellent resistance to carburizing and nitriding atmospheres, superior oxidation resistance, and a low thermal expansion coefficient, which contribute to long operational life and reduced maintenance in heat-treatment plants.Q: Where can Apm Radiant Tubes be applied?

A: These tubes are ideal for use in industrial furnaces, heat-treatment plants, and specifically in gas-fired or electric radiant tube furnace systems, supporting both small-scale operations and large manufacturing facilities.Q: What customization options are available for Apm Radiant Tubes?

A: Customers can specify dimensions such as inside and outer diameter, wall thickness (3 mm to 10 mm), length, and choose between plain ends or flanged connections, ensuring seamless integration into diverse furnace designs.Q: How does the manufacturing process enhance tube performance?

A: Using powder metallurgy and hot rolling or extrusion techniques, the Apm Radiant Tube achieves a homogenous structure, high tensile strength (up to 1200 MPa), and excellent resistance to oxidation and thermal cycling, providing greater durability in harsh environments.Q: When should you consider using an Apm Radiant Tube over standard alloys?

A: Apm Radiant Tubes are preferred in scenarios where prolonged exposure to high temperatures, corrosive atmospheres, and frequent thermal cycling are expected, as their advanced alloy composition ensures extended service life and dependable operation.Q: What benefits do Indian distributors and exporters offer for Apm Radiant Tubes?

A: Indian suppliers provide access to standardized and customized Apm Radiant Tubes, competitive pricing, and expert support for selection and integration, serving both domestic and international markets.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

PR SHAH & CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |